Drones offer the energy industry reliable and cost-effective solutions, significantly improving the efficiency, safety, and accuracy of site inspections. Dfwairview provides access to a vast network of skilled and licensed drone pilots nationwide. These professionals are adept at swiftly navigating through large expanses of challenging terrain, including rugged landscapes and dense forests, to conduct thorough evaluations of project locations.

Various sectors within the energy industry can harness the power of 3D modeling, LiDAR technology, and industrial photogrammetry to address essential requirements. Whether enhancing the efficiency and accuracy of asset inspections or surveying an area ahead of constructing an energy facility, our drone services offer invaluable insights for effective site management.

The wind power and telecommunications industries heavily rely on high-elevation assets such as turbines and towers. Drone imaging offers several advantages in this regard:

1. Enhanced Equipment Inspections: Our Dfwairview drone pilots can optimize flight routes to swiftly inspect equipment and assets, covering over 600 acres in a single day. This expedites a typically time-consuming process and allows for increased inspection frequency.

2. Change Monitoring and Updates: Automated flight routines enable easy before-and-after comparisons to track changes over time, facilitating maintenance scheduling based on predictive analytics of asset maintenance needs.

3. Defect and Damage Capture: Drones, with their closer proximity, can accurately capture damage and defects caused by weather and wear, enabling precise maintenance to extend equipment and asset life.

4. Improved Worker Safety: Most maintenance inspections can be completed with the initial scan, keeping teams on the ground and minimizing safety risks and liability concerns.

5. Integration with Asset Management Systems: Drone inspection data can seamlessly integrate with existing asset management systems, streamlining maintenance scheduling, component orders, and identifying warranty repair opportunities before warranties expire.

Dfwairview’s FAA-certified and insured drone pilots stand ready to assist with wind turbine and cell tower management. Contact us to explore how we can support your operations.

Dfwairview is at the forefront of delivering drone solutions for solar energy site management, leveraging the latest in aerial technology to optimize operations and maximize efficiency. With our team of experienced, FAA-licensed, and insured pilots, we offer comprehensive services tailored to meet the unique needs of solar farms.

Our expertise spans various aspects of solar farm management, including:

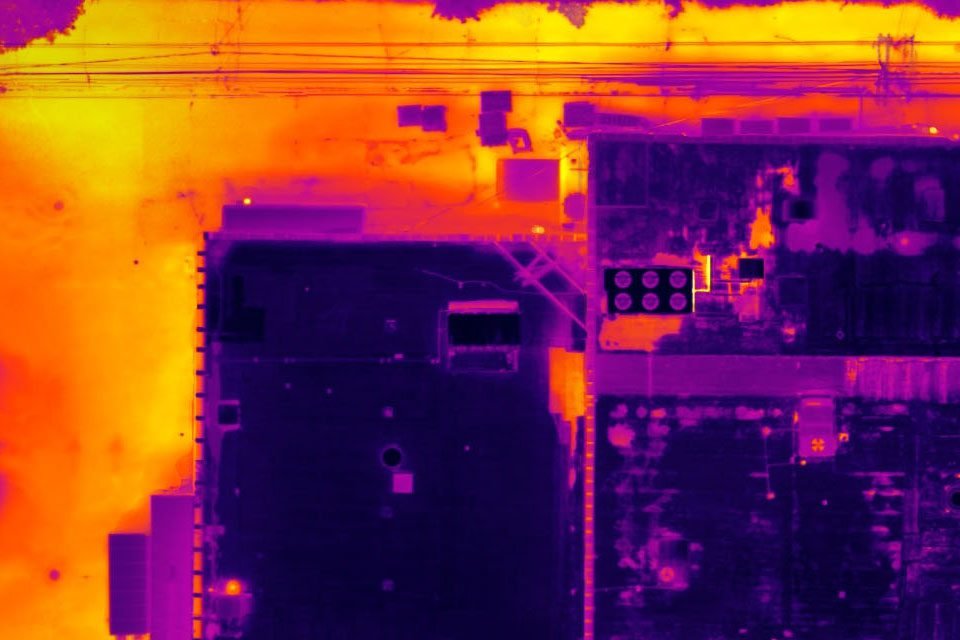

1. Pre-construction surveying and mapping: Utilizing advanced drone scanning techniques such as LiDAR, infrared imaging, and high-resolution RGB photography, we provide accurate data for site assessment and design optimization.

2. Enhanced energy yield analysis: Through thermal surveys and comprehensive inspections, we identify areas of underperformance and potential issues affecting energy production, enabling proactive maintenance and optimization strategies.

3. Regulatory compliance monitoring: Our drone inspections help ensure compliance with environmental regulations and safety standards, minimizing risks and liabilities associated with solar farm operations.

4. Asset management and maintenance planning: With detailed aerial imagery and data analytics, we support asset management efforts by providing insights for maintenance scheduling, equipment monitoring, and performance optimization.

Dfwairview is committed to delivering reliable and cost-effective drone solutions for solar energy site management. Contact us today to learn more about how we can support your solar farm operations and maximize your energy production capabilities.

In recent years, the oil and gas sector has experienced significant growth driven by escalating demand from emerging markets. However, this expansion has brought forth a plethora of challenges, including heightened production costs and environmental apprehensions. To address these hurdles, the industry is increasingly turning to drones, which offer a cost-effective solution for obtaining high-resolution imagery.

Drones play a crucial role in various facets of the oil and gas industry, including equipment and facility inspections, pipeline leak detection, surveillance of remote sites for illegal activities, as well as rig and platform inspections. Additionally, drones are utilized for tasks such as drilling site selection, reservoir analysis, and monitoring well integrity, contributing significantly to operational efficiency and environmental management within the industry.

Utilizing drones, companies can expedite the process of identifying new drilling sites by acquiring high-resolution images of prospective locations. These drones assist in pinpointing areas where potential obstacles, such as mountains or geographical features, may impact drilling operations. By leveraging this technology, companies can streamline decision-making processes, ultimately saving both time and resources. Furthermore, the ability to avoid areas that pose significant challenges or are economically impractical for resource extraction, such as deep underground shale gas deposits, contributes to more efficient and cost-effective exploration endeavors.

Drones play a vital role in analyzing reservoirs, a critical aspect of oil and gas projects. Through drone surveys, the condition of rock layers and their interaction with wellbores can be assessed. This information aids in determining essential factors such as the volume of drilling fluid required for wellbore operations, the reservoir’s water retention capacity, and the identification of cracks or faults within the reservoir. By leveraging drone technology for reservoir analysis, companies can enhance their understanding of subsurface geological formations and optimize drilling operations for improved efficiency and productivity.

Using ultrasonic sensors, infrared cameras, and thermal imaging devices, drones can conduct up-close and non-disruptive inspections to detect structural defects, system deficiencies, or potentially hazardous situations. This approach has demonstrated remarkable effectiveness in assessing the condition of oil and gas pipelines, storage tanks, and tanker ships. Moreover, by integrating drone data with advanced data analysis techniques, companies can anticipate breakdowns and leaks, enhancing proactive maintenance and risk management strategies.

One of the primary applications of drones in the oil and gas industry involves conducting internal tank inspections. Utilizing a drone provides inspectors with an elevated perspective of tanks, enabling them to identify corrosion, leaks, and other imperfections that would otherwise remain undetected from ground level.

Drones capture thermal imagery and transmit it to the operator stationed at each inspection point. Offshore drone inspections boast swifter efficiency compared to traditional methods, as they eliminate the need for on-site personnel and minimize operational disruptions.

Drones capture thermal imagery and relay it to the operator stationed at each inspection point. Offshore drone inspections outpace traditional methods in speed, as they necessitate no on-site personnel and result in minimal operational interference.

Embracing drones within oil and gas companies can markedly enhance the safety and efficiency of infrastructure inspections. Drone technology mitigates the risk of plant shutdowns and operational delays during mandatory inspections, streamlines maintenance processes, and minimizes the resources required to conduct thorough inspections.

Employing drones for equipment inspections and data collection on stacks and flares across platforms and extensive pipeline networks serves to reduce liability and averts worker injuries.

Mitigate both onshore and offshore mishaps, enhancing safety for rig workers and inspectors while preserving wildlife. In critical, time-sensitive scenarios such as defects or spills, drones can swiftly transmit real-time information, facilitating prompt and potentially life-saving decisions.

Conducting ground-based inspections at refineries and offshore sites can extend over weeks, incurring significant costs in labor hours and operational downtime. Utilizing drones enables the acquisition of more precise data within a shorter timeframe, offering cost-effective efficiency.

Oil and gas companies are bound by stringent regulations and environmental standards. Drones play a crucial role in collecting real-time data and detailed imaging, aiding in the enforcement of regulatory compliance.

Drones furnish precise data on soil quality, erosion rates, water samples, and more, enabling companies to optimize the productivity of their lands.

In response to the imperative to combat global warming and climate change, the oil and gas industry is increasingly focused on minimizing methane emissions. Consequently, companies are employing advanced sensing devices such as drones to acquire real-time data.

Dfwairview leverages a vast network of licensed and insured drone pilots across the nation, equipped with the expertise and understanding needed to survey energy sites comprehensively. Whether it’s vast expanses of wind turbines or extensive oil pipelines, our teams deliver high-resolution imagery and video for inspections or produce highly precise topographic maps, offering invaluable insights.